Get a look first-hand at Mold-Man® Machines with videos demonstrating how to operate and special features.

| MoldMan Systems™ Product Demonstration – Mold-Man® 1050 Tabletop Machine The Mold-Man® 1050 is compatible with low-pressure materials including polyamides and copolyesters. Finished products are ready to handle and test in seconds. |

| MoldMan Systems™ Product Demonstration – Mold-Man® 2050 Tabletop Machine The Mold-Man® 2050 is compatible with one or two-part silicones, urethanes, and epoxies, distributed through bulk or cartridge packaging. Finished products are ready to handle and test in seconds. |

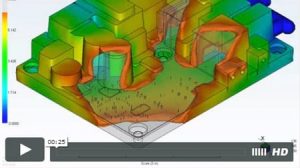

| MoldMan Systems™ Moldflow Analysis – Fill Time Watch a helpful video demonstrating a sample fill time for a low-pressure molding application. |

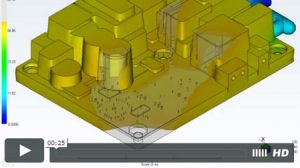

| MoldMan Systems™ Moldflow Analysis – Pressure Drop This moldflow analysis models a sample pressure drop in a low-pressure molding application. |

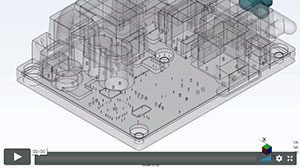

| MoldMan Systems™ Moldflow Analysis – Plastic Flow MoldMan Systems™ uses Mold Flow Analysis to analyze plastic flow within the mold-set, prior to manufacturing the mold-set, for sealing electronics and PCBs using MoldMan Systems™ Low Pressure Injection Molding. |

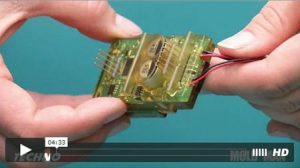

| MoldMan Systems™ – Molding on Strain Reliefs with Henkel TECHNOMELT® Mold-Man® Machines work well with Henkel TECHNOMELT® materials, featuring benefits like shorter cycle times, design flexibility, effective strain relief, and water-tight encapsulation. |

| MoldMan Systems™ – Overmolding PCBs with Henkel TECHNOMELT® Learn how Mold-Man® Machines and Henkel TECHNOMELT® materials work together to overmold PCBs with protection against dust, vibration, and impact. |

Looking to see what your own application would look like in action? MoldMan Systems™ also offers special options like moldflow analysis and moldset creation, allowing you to design and create the perfect moldset. Contact us today to learn more.